Improved longevity for CAC cores

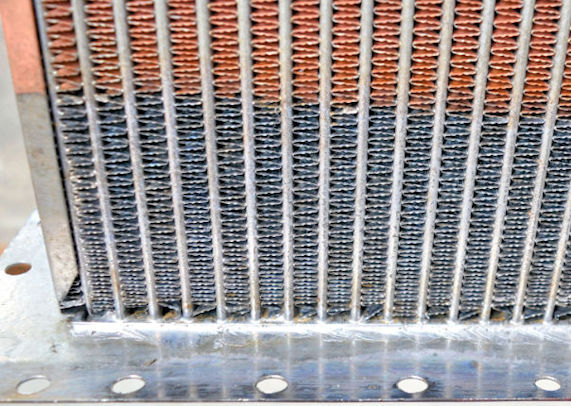

G&M have developed a method of dipping the header plate and first 80mm of tubes and fins in high temperature solder for use in charge air coolers.

Some turbocharged industrial engines operate with very high charge air inlet temperatures. This means that even if the tube plate of the CAC is dipped in high temp solder the extreme heat can travel down the first part of the core and can weaken the bond between the tube and fin, compromising the strength and longevity of the core. We can apply this process to all our core constructions.

Contact our sales team for more information.